Distributed Blue Hydrogen Production Using Low-Temperature Plasma

PROJECT PARTNERS:

SoCalGas

Jet Propulsion Laboratory

Seton Hall University

National Energy Technology Laboratory

CRITICAL NEED

Hydrogen is currently a $122 billion industry with approximately 70 million tonnes produced annually, nearly all from large-scale steam methane reformers (SMRs) at a cost of about $1.50 per kg and generating about 10 kg of CO2 per kg of H2. Growth in the hydrogen market is anticipated to exceed $200 billion of market value with corresponding size of 120 million tonne per annum by 2026, driven in large part by emerging markets in transportation, fuel cells, heating, steel production, stationary power generation, etc. Some of these applications ideally require hydrogen in 100 kg/day to 10 tonne/day scale and currently this distributed H2 need is met by a combination of bulk H2 delivery (liquid/gaseous trailers) and small-scale SMR generators. The current market price of the delivered H2 to an end user varies between $10 to $14 per kg, impeding its wide scale application for zero emission systems. This price must be reduced below $4 per kg along with significant reduction in CO2 footprint to enable growth of these new hydrogen applications.

PROJECT INNOVATION + ADVANTAGES

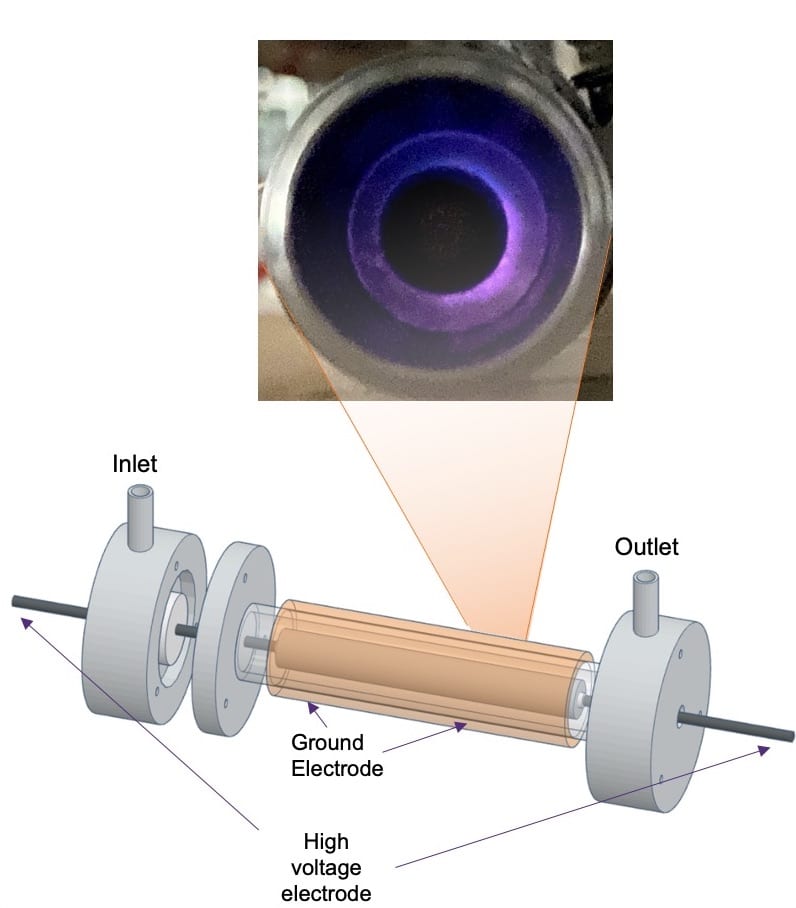

Susteon is developing a compact distributed H2 generator with a goal to produce high-purity pressurized hydrogen at $3 to $4 per kg while capturing CO2. This technology is based on a catalytic nonthermal plasma originally developed by NASA’s Jet Propulsion Laboratory (JPL). This nonthermal plasma – based on dielectric barrier discharge – activates methane in a specially designed reactor over a Ni-based reforming catalyst at ~300°C to produce a high-hydrogen containing syngas which is purified and compressed to produce high-pressure, high-purity hydrogen and CO2 streams. The overall energy efficiency of this system is approaching 70% compared to 52% for water electrolysis and ~60% for the distributed SMR-based systems. This process has been successfully demonstrated at lab-scale and currently being tested at a 1 kg/day prototype. Plans are to build a 100 kg/day demonstration unit by end of 2021.

POTENTIAL IMPACT

Successful development of this technology will enable growth of emerging new distributed applications of hydrogen to meet the overall net zero emissions goal at competitive costs. Fuel cell electric vehicles and other fuel cell-based applications such as forklifts (used extensively in warehouses) could be early applications of this technology.